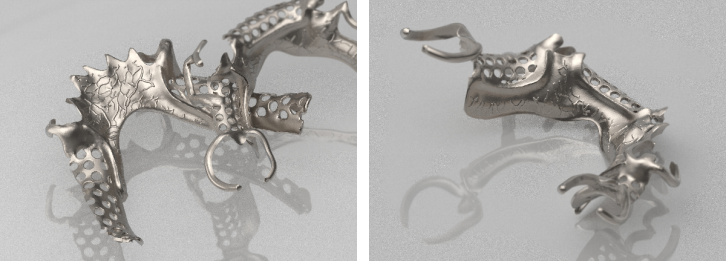

Removable dentur

The DPR-M01 applies not only fixed denture but also removable denture, which truly enables the production of the two artificial denture with one powder, avoiding the workload of changing powder and improving the efficiency of the equipment. Also compared to casting, 3D printed oral stent are lighter and thinner, making them more patient-friendly.

Fatigue of clasp

The clasp plays the role of retaining, stabilizing and supporting for removable partial dentures. They are used frequently and have strict requirements on fatigue performance. The parts printed by DPR-M01 have no obvious decay in the retention force after 10,000 cycles, and with no significant change in the shape of the ring. This not only meets the clinical needs, but is also higher than commercially similar products.

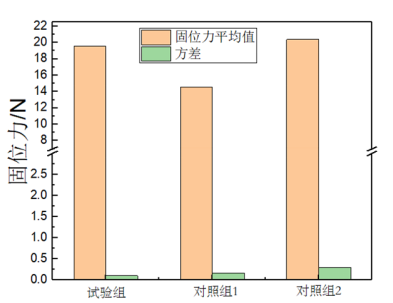

Fatigue test of clasp

The mean value of the retention force during cyclic removal in the test and control groups

Fatigue of large connector

The connector connects the various parts of the denture together and also has the function of transmitting and distributing jaw forces. The requirements for deformation and fracture resistance are strict. Through the response test, the large connector by DPR-M01 was slightly deformed after 10,000 cycles, but the deformation is smaller compared to foreign imported powder printed parts. Cracking and fracture did not occur. Not only does it meet clinical requirements, but it is also higher than similar products of the same type.

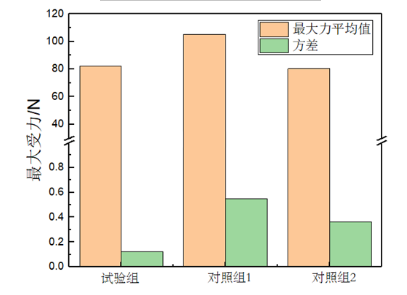

Actual test procedure

Changes in force during the test

Post-processing and polishing

The 3D printing process has developed a unique support structure for the DPR-M01, which not only facilitates supports’ removal but also provides good control of deformation caused by internal stress. A complete polishing solution is available for post-processing and polishing after printing.